Tumble lube works on standard lube groove bullets, as well as on tumble-lube-bullets. Your should try these approaches to see how they work for you, and see which one your 357 revolver likes the most.

Here are three TL358-158-SWC bullets, one of the most accurate and best designed bullets that I've found. The first is lubed with Lee Liquid Alox (LLA) mixed with mineral spirits, followed by a dusting of mica. The middle bullet is a clean, sized bullet to act as a reference. The third is lubed with Johnson Paste Wax:

- First: Prepare the bullets with WD40, lightly spray a bunch of bullets spread on a paper towel, and then run them through the sizer (don't let them dry before sizing). This avoids having to lube twice. It takes time for them to dry, which can be avoided and isn't needed. A penetrating oil/lube like WD40 isn't good for gunpowder, however the lube will coat it, and prevent any problems.

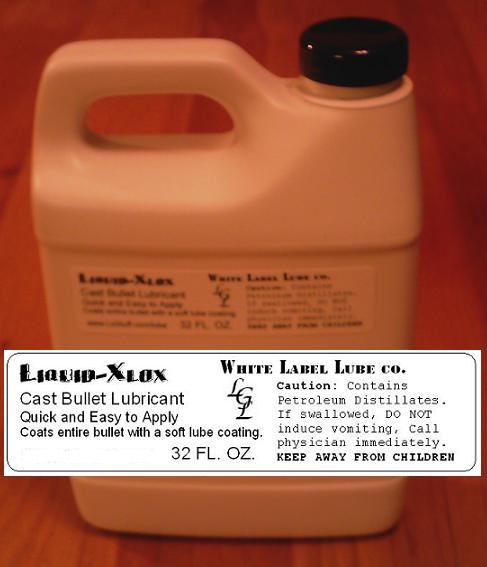

- Second: Prepare the lube, mix your Alox with Mineral Spirits, 2/1. This mix cuts the pure Alox or Xlox, making for a thin even application. Unless too much lube is used, it dries nicely, with very little stickiness.

- Third: Tumble lube per the Lee instructions, then spread on wax paper to dry. Use a small fan to help the lubed bullets dry more quickly, if one is handy.

- Fourth: Put the lubed bullets into another container, add a small (very small) amount of mica and swirl it around. Just like lubing.

The mica can be bought from Midway, and probably other online sites too:

Approach 2

Johnson Paste Wax is becoming my favorite lube, it's awesome. However testing isn't complete, hot loads will be put through the paces soon. For lighter loads, the jury is in, it can't be beat in my opinion. It lubes great, is accurate, and less messy than traditional lube or liquid Alox.

Update: JPW works great with tumble lube design bullets. However it did fail to lube a 170 grain Keith bullet, resulting in leading. Keep that in mind when lube your bullets. I plan to shoot a lot more of it with light, very accurate loads. For full house Keith bullets I will continue to Lubrisize with Darr lube.

- First: Prepare the bullets with WD40, lightly spray a bunch of bullets spread on a paper towel, and run them through the sizer (don't let them dry). This avoids having to lube twice, once before lubing. It takes time for them to dry, which can be avoided. A penetrating oil/lube like WD40 isn't good for gunpowder, however the lube will coat it, and prevent any problems.

- Second: Put the bullets into a plastic bag or container and let is sit for 5 minutes in hot tap water. This will warm the lead and will help the wax coat evenly. They should be slightly warm to the touch, not hot and not cool.

- Third: Scoop a small amount of the Johson's Paste Wax into a container of bullets. For 200 bullets, try a dime size glob of wax.

- Fourth: Tumble lube just like Approach 1, then spread on wax paper to dry. Use a small fan to help the lubed bullets dry more quickly, if one is handy.

In Conclusion:

There are many other approaches that work too. However, these are the techniques I use most often these days and just may work well for you too.

One other very noteworthy approach was created by Recluse, a member of castboolits.gunloads.com. He created a mix called 45/45/10 that is hugely popular. It's 45% LLA, 45% reduced JPW and 10% mineral spirits. Search with Google and you'll be able to find it quickly. The detailed instructions are excellent and are available at that forum.

Shoot well!

There is a follow on post at: http://357shooter.blogspot.com/2011/06/update-best-way-to-lube-best-cast.html

Can you tell me a little bit more about the bullet lube does? I'm curious to see if it really does help me gun as much as you say it does. If it helps me with my hunting hobby then I say, why not?! But tell me how it works. I like to know exactly what I'm using on my gun.

ReplyDeleteHi Gary,

ReplyDeleteBullet lube is used on cast lead bullets. Store bought cast bullets come lubed, those of us that cast our own then have to lube our own.

It doesn't apply to jacketed or plated bullets, FYI.

The purpose of lube is to help prevent leading of the barrel. Lead buildup ruins accuracy, sometimes in as few as 20 rounds, sometimes it takes 100 or more rounds.

The two major choices are to lube with a lubrisizer or pan lube. Both methods fill the bullets grease groove with lube. The other major choice is to tumble lube. This post addresses tumble lubing, and the pictures show bullets designed specificially for tumble lubing.

I hope that helps explain it.

This comment has been removed by the author.

ReplyDeleteGary,

ReplyDeleteHi again. I missed the link you included.

That isn't a lube for cast lead bullets, per se, and not something I've recommended, FYI.

The mica that I listed is graphite, but is used by dusting the actaul tumble lube to help make it less sticky.

Are you casting & handloading bullets for your 357?

This comment has been removed by a blog administrator.

ReplyDelete